Do You Have A Construction Project We Can Help With?

![]()

Q: Does Gingfisher fade or change color?

A: There are several factors that cause fade. Bad weather, sunlight exposure and heavy foot traffic play a major role in the fading process of a deck. How well your Gingfisher deck endures Mother Nature depends upon what type of Gingfisher you have.

Uncapped composite decks do not have the high-performance shell with enhanced fade, stain and mold resistance. As such, these traditional composites will fade naturally over time, achieving their weathered color after 12-16 weeks.

UV stabilizer have been added to Gingfisher to reduce color fading due to extensive sun exposure. A slight change in color will occur but will retain this lighter shade through out the life of the product.

color chart for color changes.

Newer generation high-performance composites—-capped composite decking have the protective shell technology that provides superior fade and stain resistance.

Q: Why is Gingfisher Decking Better than Wood?

A: Ginfisher products offer superior durability and performance that you can’t get from wood. Gingfisher Decking resists termites, won’t rot, warp, or splinter-and never needs staining or painting. What’s more, Gingfisher decking is made from recycled materials: that’s an eco-friendly decking choice you can feel great about.

The up front cost of composite decking is more than that of pressure treated wood. However, that is offset by a useful life that’s significant longer.

Buying wood means you will have to incur the cost of replacement sooner. In addition, the maintenance costs of Wood are greater because composite decking requires less maintenance.

wood vs composites

Q: Does composite decking get hot in the sun?

A: We often get asked what is the coolest decking in our low- maintenance options. All decking was hotter by being in direct sunlight. wood-plastic composite decking as with most outdoor building products, can retain heat-especially after a long day in direct sunlight. All things considered, the benefits that low-maintenance decking provides, far outweigh the heat retention that it has.

At Gingfisher, we have taken steps to minimized heat build- up with certain formulations of our products. Our technology optimizes heat reflection and reduce heat transfer on contact.

Also, this will depend partly on the color of the material. Lighter colored decking will tend to reflex more of the heat, where darker colors will absorb the heat and tend to get hotter faster reaching higher temperatures.

Cooler Composite Decking

Q:How long does composite decking last?

A: Composite decking is known for its long life. Since the plastic protects the wood fibers from the elements, composite decking isn’t prone to rotting, decay, or termite damage. Gingfisher Composite decking often comes with lifespan from 10-25 years that guarantee it won’t rot or suffer structural damage under normal residential conditions.

Gingfisher decking will look just as good throughout its lifespan as it does when newly installed.

Our Lakeside Project after 10 years

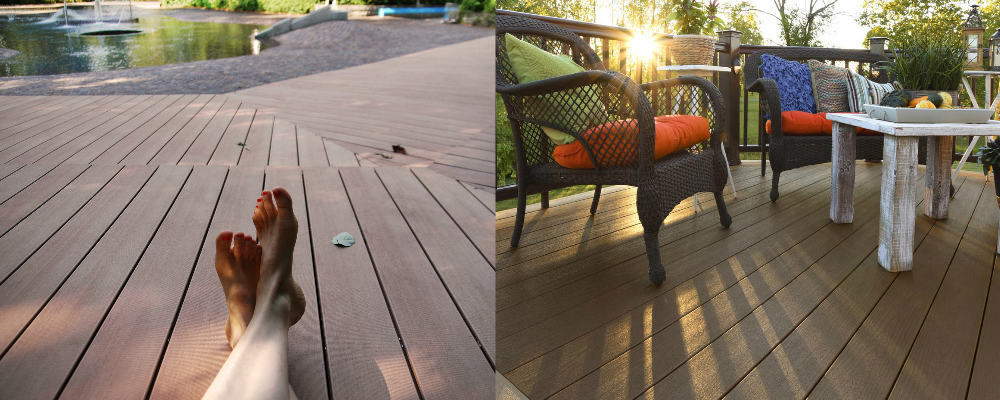

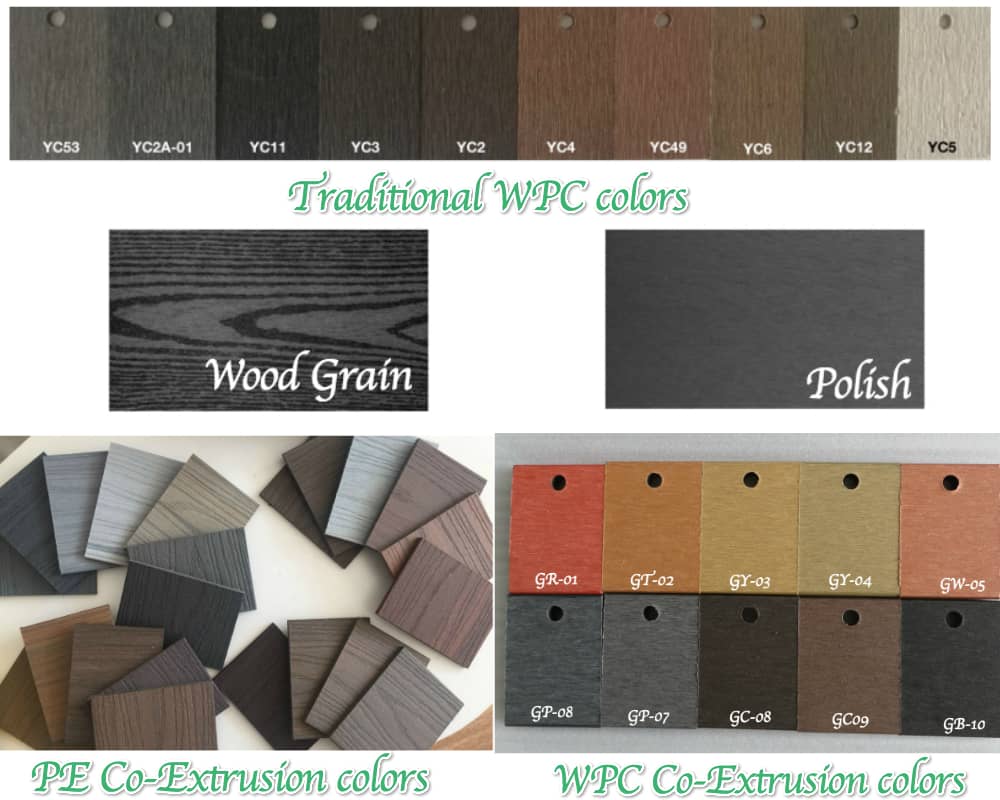

Q: What colors and styles are available?

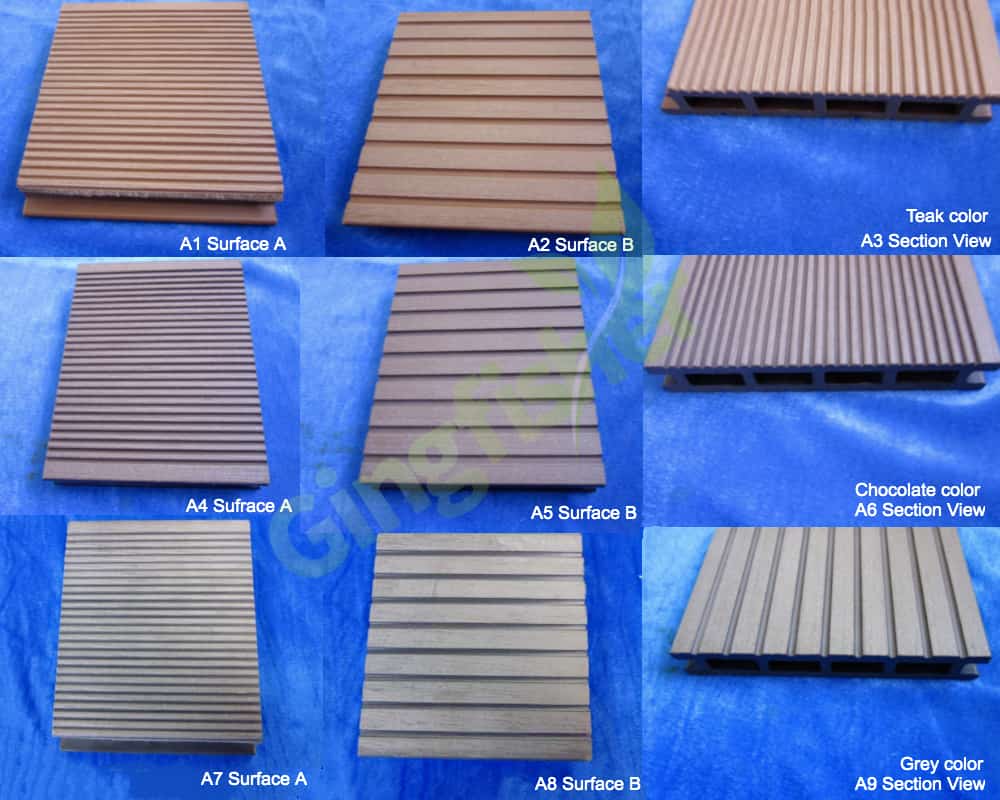

A: Gingfisher Composite decking comes in wide variety of colors, textures, and wood grain looks, so homeowners or contractor can find the right product for just about any decking project. Choose from natural looking wood colors like teak and walnut, or go with a stained gray or silver look. Grooved and smooth boards are also available, as are a variety of reversible options that feature a simple brushed texture on one side and a realistic wood grain texture on the other.

gingfisher color choices

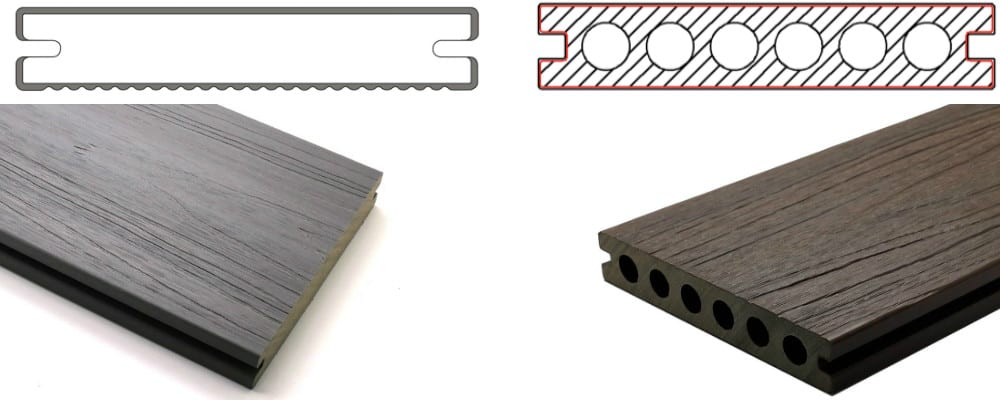

Q: What’s the difference between hollow and solid core boards?

A: Some homeowners prefer solid boards because they look more like the real lumber traditionally used for decking.

solid boards, because of their denser construction, are particularly strong. If you plan to load down your deck with heavy objects, such as hot tubs, grills, and furniture, solid boards might offer the most stability.

Building your own deck is a labor-intensive process. If you want to work with lighter-weight materials, you could benefit from hollow boards, which weigh considerably less than their solid counterparts. You might have an easier time transporting and positioning the boards, as well.

Both Board Options provide a strong and quality deck you can count on.

Solid vs. Hollow Decking

Q: Can grooved deck boards be used for stair treads?

A: No, we do not recommend using grooved deck boards for stair treads for two reasons. First, the groove will be facing out and will not be aesthetically pleasing. Second (and most important), the long-term performance of the board may be compromised. Here’s why: When someone is walking up a staircase, the bulk of his/her weight is distributed across the front of each step. This is where the groove is located; therefore, over time, the groove could crack from the continual weight bearing down on it. We recommend using only square edge deck boards for stair treads.

Gingfisher staircase project

Q: Is Gingfisher Structural?

A: Gingfisher Wood Plastic Composite products are not structural and should only be used for intended design purposes such as walking surfaces, guardrail systems, fencing and trim;

Gingfisher composite decking has many outstanding qualities; however, it is simply too flexible for use as a structural component of the deck.

Recommend Aluminum, steel or treated wood as structure. Please note, composite products’ lifespan is related to stable and durable structure.

Gingfisher Galvanized Steel Structure

Q: Can Gingfisher Decking be installed over existing joists and framing?

A: Yes, Gingfisher can be installed over an existing substructure if the following conditions are met:

- The existing framework must be free of any damage or decay and in good, workable condition (consider having the space assessed by a licensed deck inspector).

- The joists must be spaced correctly.

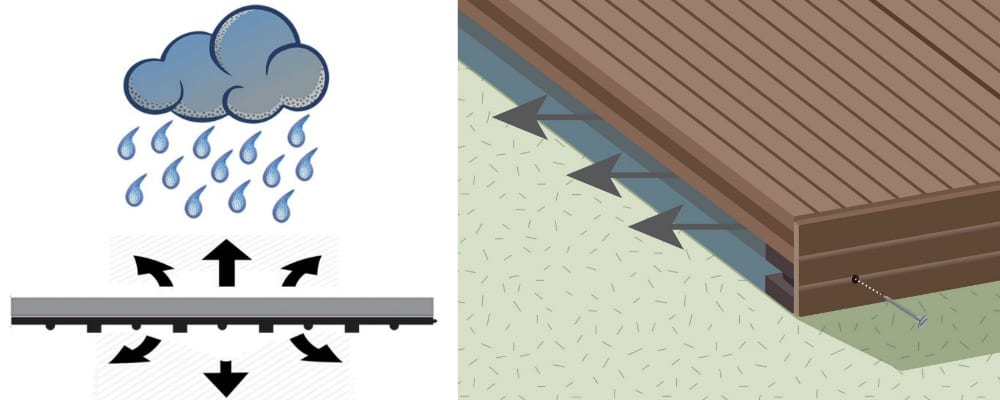

- There must be adequate cross ventilation and unobstructed airflow under 50% of the deck. Allow a minimum of 1.5 inches (4 cm) between bottom of joist and the ground. Water must be able to flow away from under the deck. Improve drainage or grade flat areas where standing water may gather, and do not install decking directly to an existing or solid surface.

Gingfisher UK Project

Q: How much space is needed between deck boards for proper drainage and ventilation?

A: Allow a minimum of 3/16 inch. between Gingfisher composite boards (side to side) to ensure proper drainage and ventilation and to assist with the removal of small organic debris. Allow a minimum of 1/4 inch. spacing between boards and any permanent structure.

Depending on the weather and temperature conditions on installation day, the amount of normal expansion and contraction of the boards will vary. Darker colors will naturally expand more than lighter colors, in much the same way that darker objects heat up more in the sun than lighter ones. However, to help control end-to-end spacing, all decking should be kept at ambient temperature and shaded from direct sun prior to cutting and installing.

Anyway, Gingfisher composite decking should be installed in the floor with good Drainage system, good air circulation system and no ground water.

proper drainage and ventilation

Q: Does composite decking require maintenance?

A: Composite decks require minimal maintenance. Regularly clear off any debris like leaves, dirt, and dust. Give your deck a more thorough clean at least twice a year using just a brush, hose, and mild household cleaner. Don’t use power washers, as they can damage composite decks. Unlike wooden decks, composite decking doesn’t require staining, waterproofing, or sealing.

Gingfisher composite decking is not only a beautiful addition to the home, but can offer many advantages over traditional wood decking.

It is crucial to know how to properly care for a composite deck and taking the right steps will make all the difference.

Gingfisher decking clean & care

Q: Can I paint or stain composite decking?

A: Experts don’t recommend painting or staining composite decking, since the material is impregnated with a dye that will last as long as your deck does. If you do opt to paint or stain your composite deck, it will require regular upkeep, similar to the maintenance required for wooden decks.

Gingfisher decking no need painting

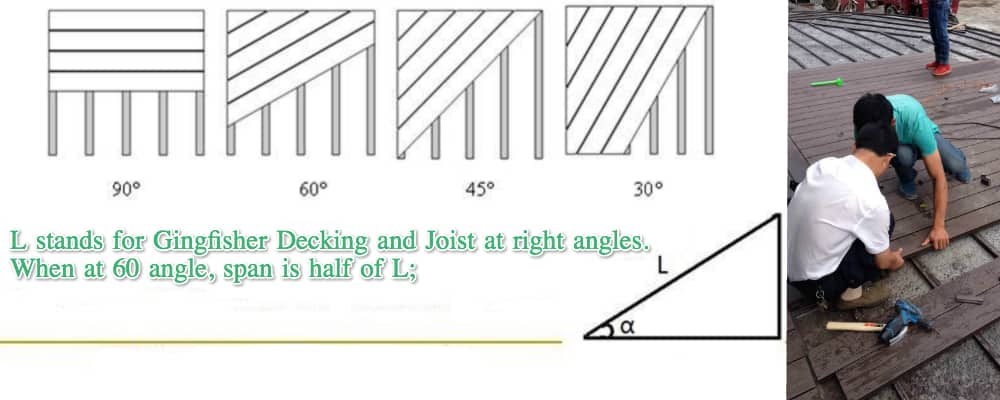

Q: What span length can I do with composite decking?

A: For perpendicular applications, the span should be 12 to 16 inches between joists. Experts recommend spans of 16 inches for a strong and solid deck. If you install at a 45-degree angle, a maximum of 12 inches on center will give the best result.

Gingfisher Decking Joist Span Advice

Q: Do I need special equipment or tools to install composite decking?

A: You don’t need special Tools to install Gingfisher composite decking, but you do need standard woodworking tools for cutting and building. Since composite decking materials cut just like wood, you can use a circular saw or a miter saw for installation. This type of decking also accepts nails and screws like real wood.

standard installation tools

Q: How much does composite decking expand and contract?

A: Composite decking does expand and contract as temperatures rise and fall, and the exact amount depends on the difference between the temperature during installation and your local area’s maximum temperature. In general, allow 3/16 inch to 1/4-inch gaps between boards to allow for expansion and contraction as well as to let dirt and water flow away naturally.

Please note, using double support joists and separate clips for each board end, when two decking boards are placed end to end.

fix these two gingfisher decking separately

Gingfisher Technical Specifications

Traditional Composite Decking (uncapped)

Gingfisher decking board is no ordinary deck board, each board is strictly according with EU and ASTM standards. Made with both HDPE and Wood this product provides you with their unique properties rolled into one single base material with the low maintenance and durability of HDPE and the appearance and strength of wood.The result of this is a decking product of extremely high quality, which exhibits excellent slip resistant properties tested against the Health and Safety Executive’s grading system, as well as excellent resistance to organic growth matter.

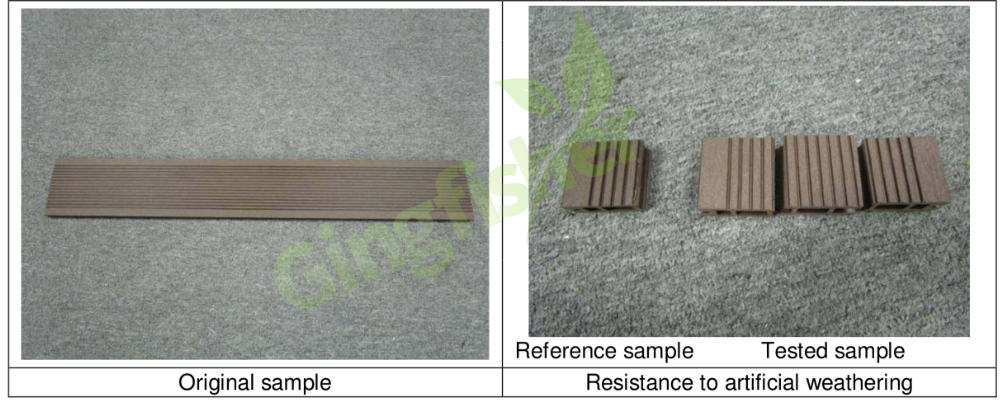

An accelerated weathering test further strengthens the view that Gingfisher decking provides the perfect performance criteria.

Gingfisher is a material that is strong, resilient, water resistant, low maintenance, slip resistant, combined with an option for an attractive, ribbed or brushed finish, as well as a range of colors to suit your particular application.

Making sure Gingfisher customers have a competitive advantage in the marketplace means providing a total quality service at best value.

Traditional Composite Decking looks more natural like real wood, if you want to check more designs, Explore now!

Part 1:

| Test Item | Test Method | Test Result |

|---|---|---|

| Appearance | EN 15534-1:2014 Clause 6.1 | No visible defect |

| Density | EN 15534-1:2014 Clause 6.2

and EN ISO 1183-1:2012 Method A |

1.29 g/cm³ |

| Moisture Content | EN 15534-1:2014 Clause 6.3

and EN 322:1993 Test Condition: (103 ± 2) °C |

0.7% |

| Linear Mass | EN 15534-1:2014 Clause 6.5 | 2243.1 g/m |

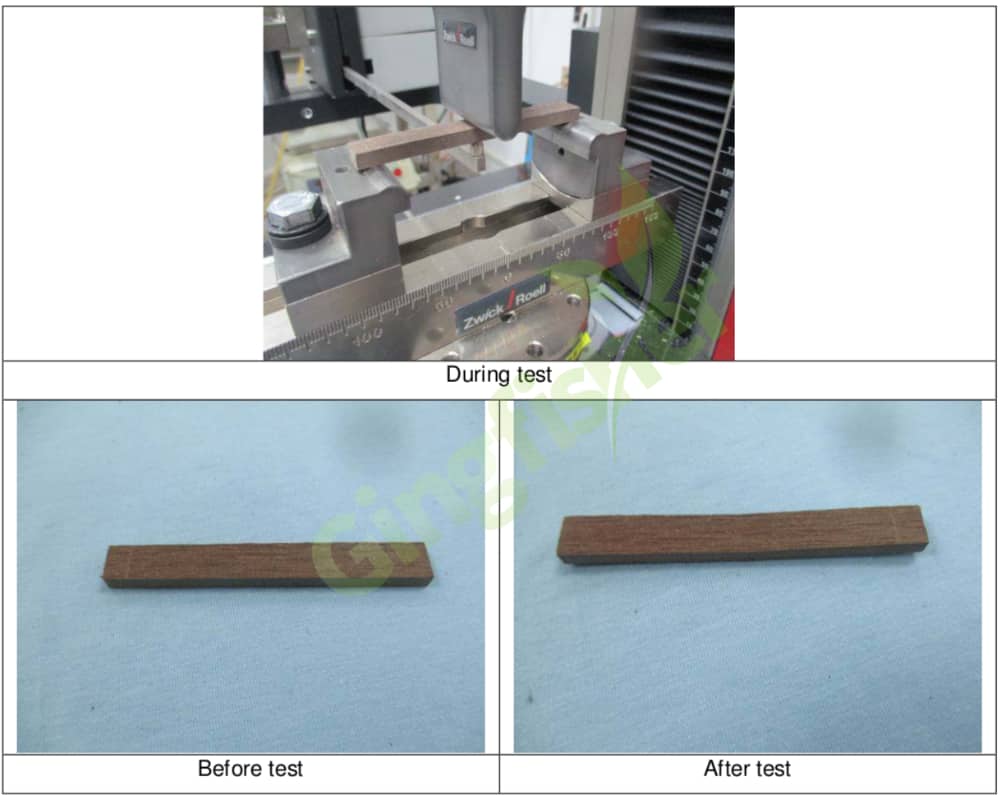

| Resistance to artificial weathering | EN 15534-1:2014 Clause 8.1

and EN ISO 4892-2:2006 and ISO 105-A02:1993 Cor2:2005 Test cycle: EN ISO 4892-2: 2013 Cycle 1 102 min light at (65±3)°C BST, (50±10)% RH 18 min light and water spray Exposure period: 300h |

∆E*ab=2.93 Grey scale: 3-4 |

| Swelling and water absorption

(Swelling after test ) |

EN 15534-1:2014 Clause 8.3.1

and EN 317:1993 Test condition: Immersion in water at 20±2°C, 28 days |

Mean value: Length 0.4%

Max. Value: Length 0.4% |

| Swelling and water absorption

(water absorption) |

EN 15534-1:2014 Clause 8.3.1

and EN 317:1993 Test condition: Immersion in water at 20±2°C, 28 days |

Mean value: 3.7%

Max. value: 3.9% |

| Moisture resistance-Boiling test | EN 15534-1:2014 Clause 8.3.3

Test condition: Immersion in boiling water, 5h |

3.3% |

resistance to artificial weathering test photo

Part 2:

| Test Item | Test Method | Test Result |

|---|---|---|

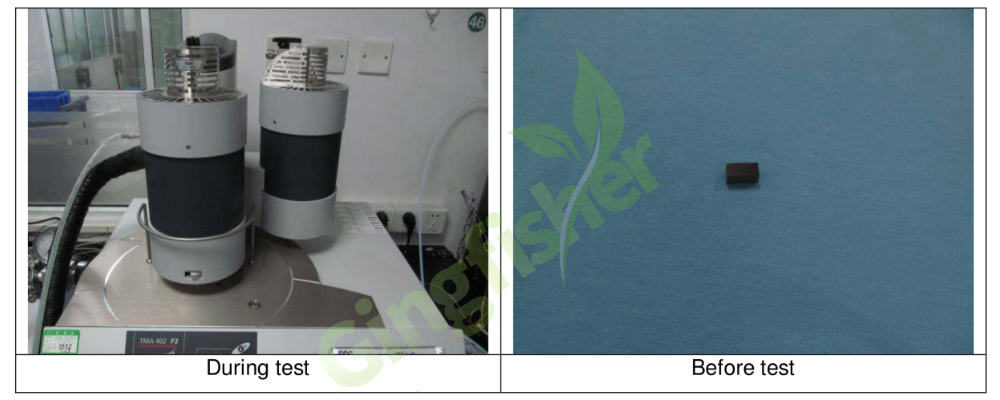

| Linear Thermal Expansion | EN 15334-1:2014 Section 9.2

& ISO 11359-2:1999 Method A Test Condition: Specimen: 10.88mm×5.07mm×5.05mm Rate of temperature: 5°C/min Load: 4kPa Flow rate(N2): 50ml/min Test temperature: -20°C~80°C Test mode: Compression Test direction: Length Number of specimens tested: 1 Lab Environmental Condition: (23±2)°C, (50±5)%RH |

44.7×10-6 K-1 |

Thermo Mechanical Analyzer

| Test Item | Test Method | Test Result |

|---|---|---|

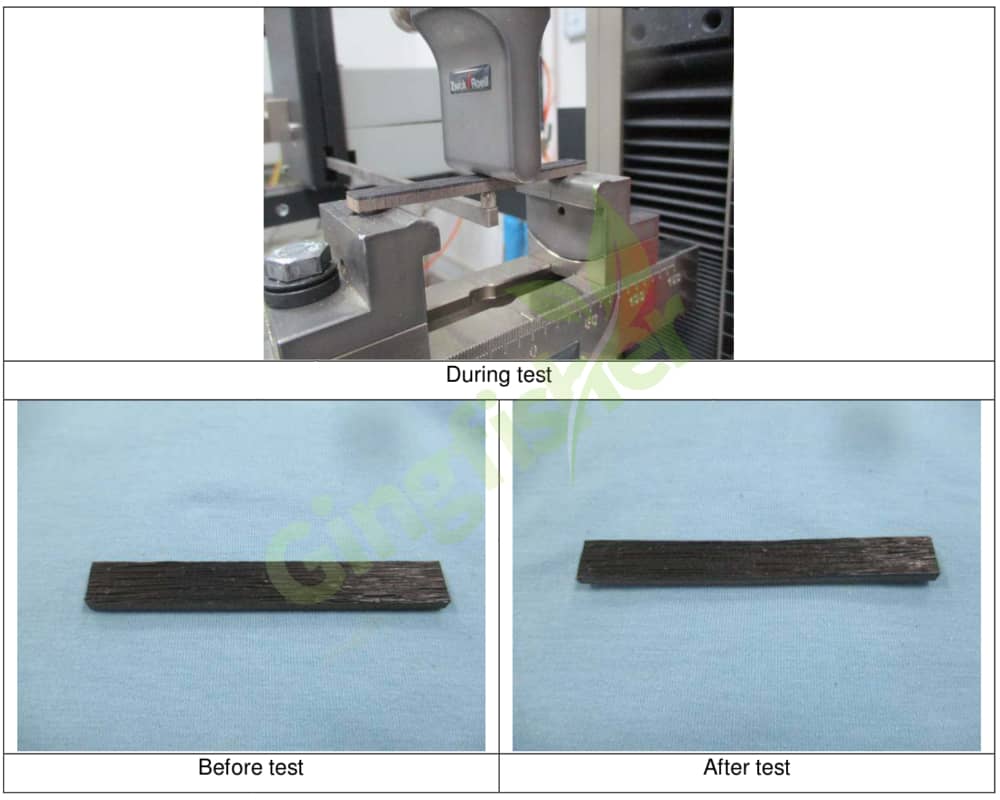

| Impact Resistance | EN 15334-1:2014 Section 7.1.1

& EN ISO 179-1:2010 |

4.4kJ/㎡

C (Complete break) |

Impact tester

| Test Item | Test Method | Test Result |

|---|---|---|

| Flexural Properties | EN 15534-1:2014 Section 7.3.1

& EN ISO 178:2010/Amd.1:2013 Method A |

Flexural Strength: 34.8MPa

Flexural Modulus: 4040MPa |

Universal Testing Machine

| Test Item | Test Method | Test Result |

|---|---|---|

| Tensile Properties | EN 15534-1:2014 Section 7.2

& EN ISO 527-2:2012 |

Tensile Strength: 19.5MPa

Tensile Strain at Break: 0.54% |

Universal Testing Machine

Part 3:

| Test Item | Test Method | Test Result |

|---|---|---|

| Creep Behavior | EN 15534-1:2014 Section 7.4.2

Test condition: Specimen: 500mm×145mm×22.2mm, 1pcs Span: 440mm The applying load: 731N Test duration: 168h |

Creep Factor:1.26

Creep Recovery (Erc): 37.9% |

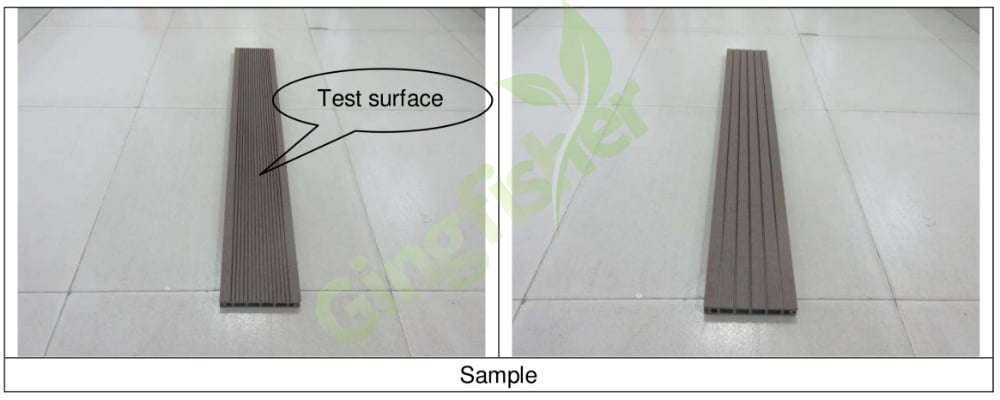

all test specimens were cut from the samples

Gingfisher Technical Specifications

Co-extrusion Composite Decking (capped)

What’s the difference between capped and uncapped composite decking?

Composite decking has always provided clear advantages over pressure-treated wood decking. Capped composite decking has a protective outer layer that is co-extruded to the wood-composite core during the manufacturing process. It is fused to the board, so there is no need to worry about the cap separating from the core.

Gingfisher’s unique cap layer contains color additives, UV inhibitors, biocides, and other ingredients to ensure your decking retains its rich, natural wood appearance without the concerns of fading, staining, mold, or mildew. Plus, when you consider that Gingfisher Capped Decking never needs sanding, staining, or refinishing, it’s easy to understand why more and more homeowners are making the smart move from wood decking to composite decking.

Part 1:

| Test Item | Test Method | Test Result |

|---|---|---|

| Appearance | EN 15534-1:2014 Clause 6.1 | No visible defect |

| Density | EN 15534-1:2014 Clause 6.2

and EN ISO 1183-1:2012 Method A |

1.27 g/cm³ |

| Moisture Content | EN 15534-1:2014 Clause 6.3

and EN 322:1993 Test Condition: (103 ± 2) °C |

0.3% |

| Linear Mass | EN 15534-1:2014 Clause 6.5 | 3021.4 g/m |

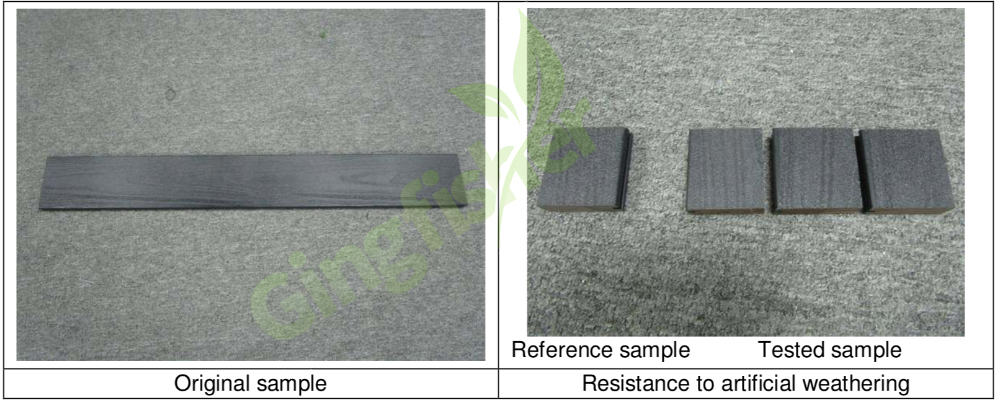

| Resistance to artificial weathering | EN 15534-1:2014 Clause 8.1

and EN ISO 4892-2:2006 and ISO 105-A02:1993 Cor2:2005 Test cycle: EN ISO 4892-2: 2013 Cycle 1 102 min light at (65±3)°C BST, (50±10)% RH 18 min light and water spray Exposure period: 1000h |

∆E*ab=1.06 Grey scale: 4-5 |

| Swelling and water absorption

(Swelling after test ) |

EN 15534-1:2014 Clause 8.3.1

and EN 317:1993 Test condition: Immersion in water at 20±2°C, 28 days |

Mean value: Length 0.2%

Width: 0.0% Thickness 0.4% Max. Value: Length 0.2% Width: 0.1% Thickness 0.8% |

| Swelling and water absorption

(water absorption) |

EN 15534-1:2014 Clause 8.3.1

and EN 317:1993 Test condition: Immersion in water at 20±2°C, 28 days |

Mean value: 0.3%

Max. value: 0.4% |

| Moisture resistance-Boiling test | EN 15534-1:2014 Clause 8.3.3

Test condition: Immersion in boiling water, 5h |

0.2% |

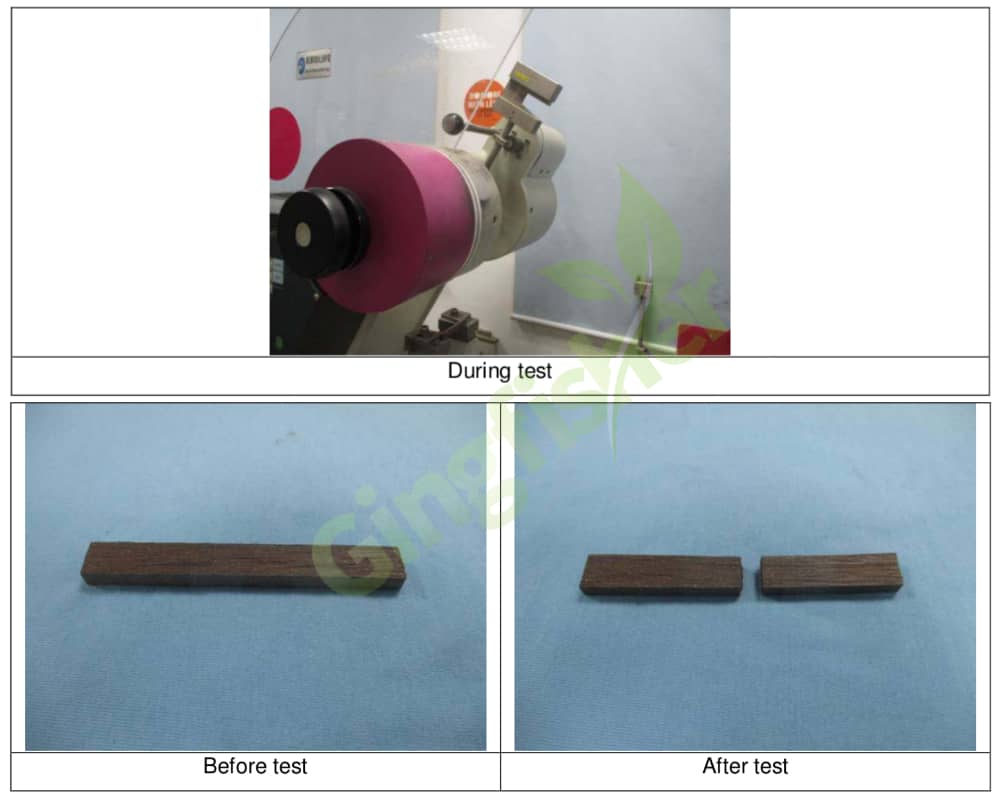

| Wear Resistance | EN 660-2:1999+A1:2003

and EN 649:2011 |

Fv=0.56mm³/100revolutions

Wear Group: Rating: T |

| Peeling Resistance | EN 319:1993 |

>3586N |

Test specimens were cut from the samples

Part 2:

| Test Item | Test Method | Test Result |

|---|---|---|

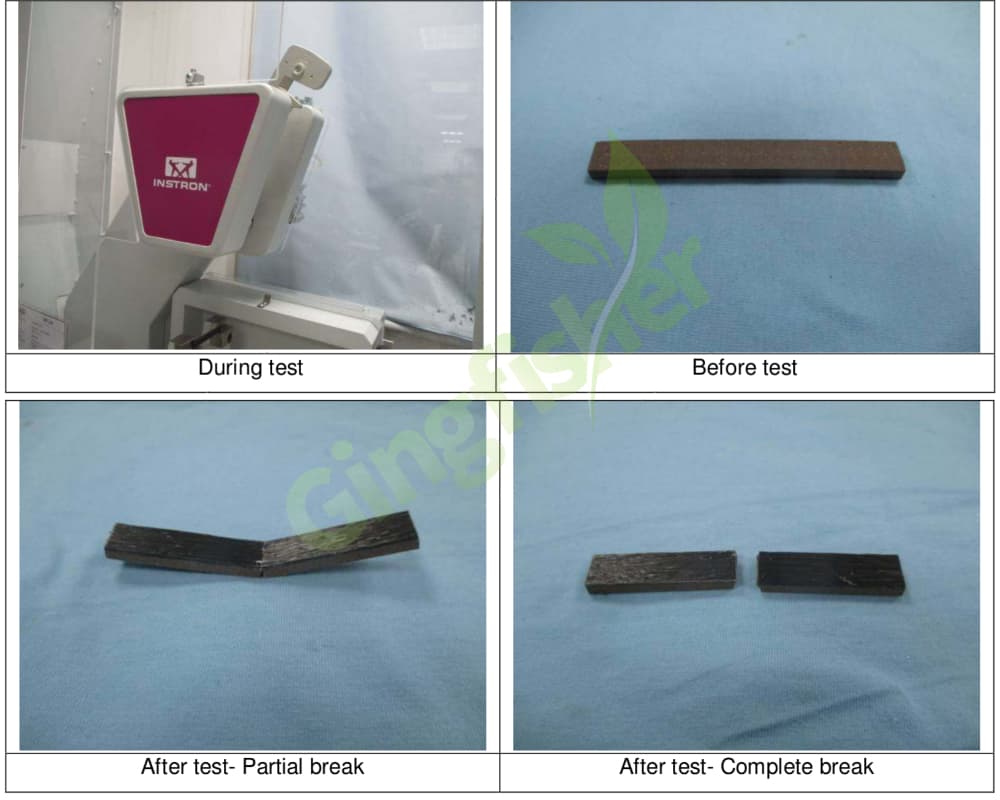

| Impact Resistance | EN 15334-1:2014 Section 7.1.1

& EN ISO 179-1:2010 Test Condition: Specimen: ISO 179-1/1fU Specimen thickness: 4.21mm The capacity of the pendulum: 1J Impact speed: 2.90m/s Span: 62mm Lab Environmental Condition: (23±2)°C, (50±5)%RH |

5.6kJ/㎡

P (C) Partial Break (Complete break)

|

Resil Impactor

| Test Item | Test Method | Test Result |

|---|---|---|

| Flexural Properties | EN 15534-1:2014 Section 7.3.1

& EN ISO 178:2010/Amd.1:2013 Method A Test Condition: Specimen: 80mm×10.19mm×4.11mm Testing speed: 2mm/min Span: 64mm Lab Environmental Condition: (23±2)°C, (50±5)%RH |

Flexural Strength: 25.5MPa

Flexural Modulus: 2430MPa |

Universal Testing Machine

| Test Item | Test Method | Test Result |

|---|---|---|

| Tensile Properties | EN 15534-1:2014 Section 7.2

& EN ISO 527-2:2012 Test Condition: Specimen: Type 1B Specimen thickness: 4.30mm Testing speed: 5mm/min Gauge length: 50mm Initial distance between grips: 115mm Lab Environmental Condition: (23±2)°C, (50±5)%RH |

Tensile Strength: 19.3MPa

Tensile Strain at Break: 0.54% |

Universal Testing Machine

Part 3:

| Test Item | Test Method | Test Result |

|---|---|---|

| Falling Mass Impact Resistance |

EN 15534-1:2014 Section 7.1.2.2.1 and EN 477-1995 Test condition: Specimen: 200mm×131mm×19.0mm Striker radius: 25mm Striker mass: 1000g Falling height: 1000mm Span: 100mm |

10 test specimens were tested, None of them show splits or cracks after test. |

| Creep Behavior | EN 15534-1:2014 Section 7.4.2

Test condition: Specimen: 500mm×131mm×19.0mm, 1pcs Span: 380mm The applying load: 682N Test duration: 168h |

Creep Factor:1.05

Creep Recovery (Erc): 41.5% |

all test specimens were cut from the samples

Part 4:

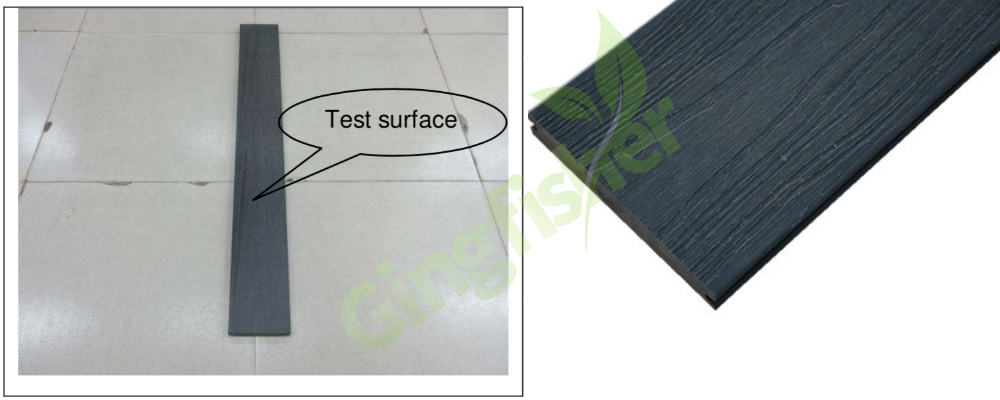

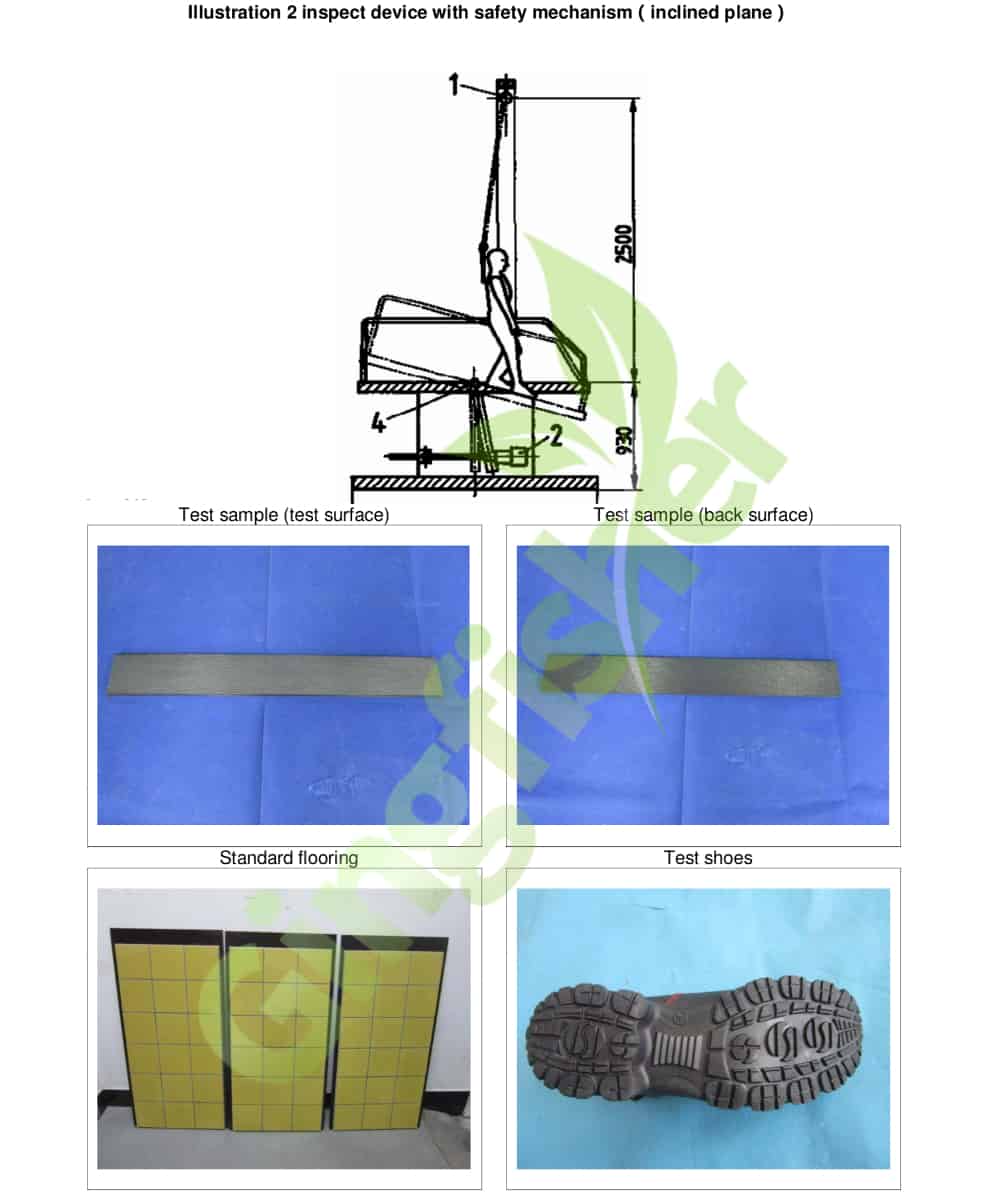

| Test Item | Test Method | Test Result |

|---|---|---|

| Slip Resistance |

DIN 51130:2014-02 |

α:10.1° Rating: R10 |

slip resistance test

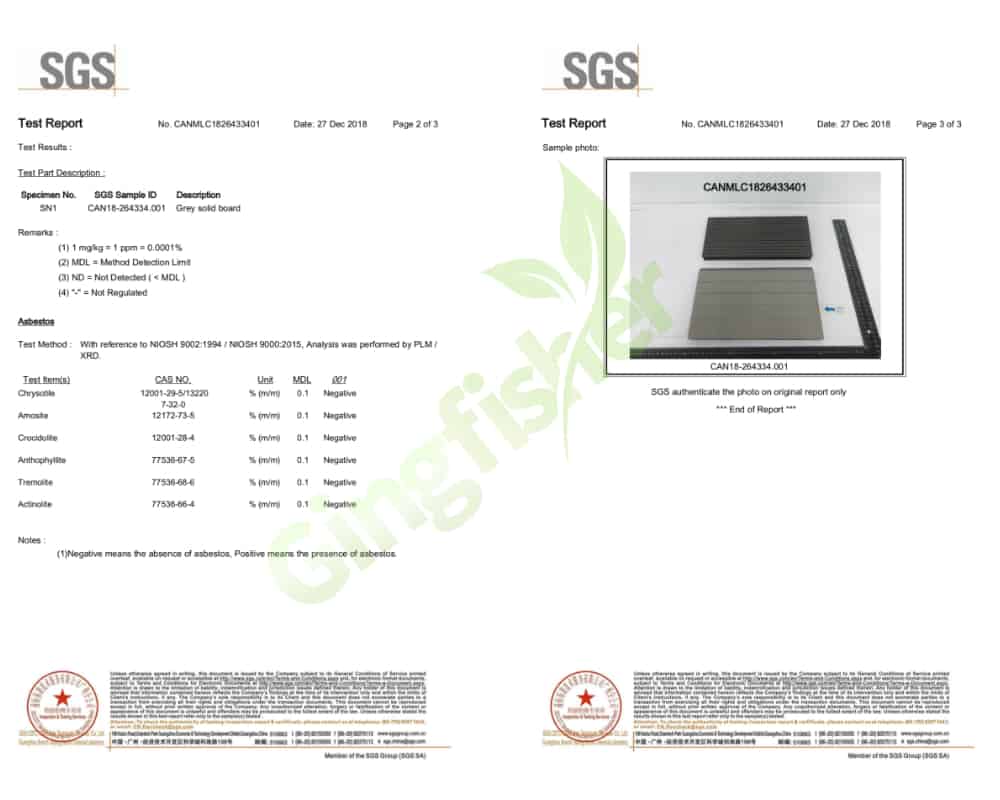

Asbestos-free Guarantee

Gingfisher Asbestos-Free Guarantee

Asbestos is a group of six naturally occurring fibrous minerals composed of thin, needle-like fibers. Exposure to asbestos causes several cancers and diseases, including mesothelioma and asbestosis. Although asbestos strengthens and fireproofs materials, it is banned in many countries. Asbestos is not banned in the United States.

Hereby, Gingfisher Guarantee that there is absolutely NO Asbestos in our raw materials of composite products.

The Australian Border Force (ABF) targets both imported and exported goods considered to be at high risk of containing asbestos.

Testing must be undertaken by an Australian testing laboratory that is accredited by the National Association of Testing Authorities (NATA).

Our test report is issued in accordance with NATA’s accreditation requirements.

Accredited for compliance with ISO/IEC 17025 – Testing. NATA accredited laboratory 2959.

Gingfisher Asbestos-free certificate

Besides Test Report from NATA accredited Laboratory, we also have test report issued by SGS.

Asbestos-free test report

Gingfisher decking no worry about Asbestos at all

SASO Certificate

What is a SASO Certificate?

For a country like Saudi Arabia, there are thousands of imports and exports that enter and leave the country every day. All these cargo and goods are used to help in the overall economy of the country and get better deals for Saudi exports in global markets. There are certain norms that need to be fulfilled if one wishes to start exporting their goods to the Middle Eastern country and also import.

For this, a certificate of conformity is required to be obtained by the business or service that is in sync with the Saudi Arabian regulations for exporting and importing.This certificate of conformity for Saudi Arabia comes under the SASO standards and is a particular set of rules and regulations that one needs to follow with regards to the product that they are planning on importing or exporting.

Gingfisher Composite products have SASO certificate and exported to Saudi Arabian successfully.

Chlorine Water Solution Test

Imagine sitting in your own backyard enjoying the beautiful sunny day with your favorite iced beverage. As you close your eyes, you can hear the gently cascading water from your brand-new swimming pool. Unfortunately, the reality of owning a swimming pool doesn’t always live up to the dream.

For the longest time, floors and decks have been built with hardwood.

But wooden floors and decks are susceptible to mold and rot, and therefore, not durable. Authentic hardwood boards are also quite expensive to buy and install.

Today, people are moving towards a more affordable, durable, and low-maintenance alternative – composite deck boards. While composite is most popular in its flooring applications, the technology can also be employed to other uses at home.

If you have a swimming pool in your backyard, composite decking is an excellent choice for the pool area because it won’t warp or splinter and is slip resistant.

Depending on the weathering and exposure to the sun, most materials will fade over time, but not with composite, especially high-quality composite like Gingfisher. Gingfisher will leave your pool area looking attractive and new over the years.

Our decking passed Chlorine water solution test is strictly according to ISO 105-A02:1993/Cor 2:2005.

Test solution: Chlorine water with 100mg/L active chlorine.

Immersed samples in 2L test solution for 7 days. The test container was air-proof to prevent Cl2 from escaping.

After one week, compared with original samples, not significant changes in color change under normal daylight.

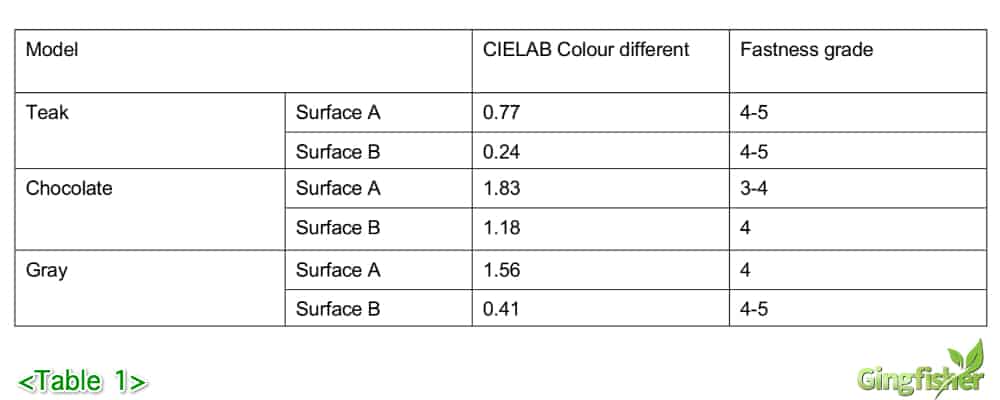

Detail result see Table 1

Chlorine water solution test Appendix A

Chlorine water solution test Appendix B

Product Appearance after test

What’s more, composite decking does not require a lot of maintenance. This will save you lots of money and time in the long run.

Happy Swimming!

pool project

Care & Clean

To maintain the beauty of your deck, a little care and cleaning goes a long way.

Learn how to clean and care for your composite decking by reading the information that applies to your decking product and get ready to enjoy maximum outdoor living with minimal maintenance.

In an outdoor environment, periodic cleaning will help your composite deck looking new. As with any flooring surface, periodic cleaning is required.

There’s no limit to how often you can clean your composite deck, but a thorough cleaning should be performed at least twice a year. Washing the area with warm soapy water and a soft cloth will usually work fine.

One of the benefits of capped composite decking is that it’s ultra-durable and resistant when it comes to common issues that typically affect wood decking materials.

TIPS FOR PREVENTING MOLD GROWTH:

Ensure proper deck gapping is achieved during installation Ensure deck board gapping is clear and free of debris. Always wash deck after heavy pollen season

Ensure proper ventilation around structure of deck

Avoid any direct water discharge from gutters or sprinklers onto deck surface

Avoid over spray of fertilizers on and around deck

Gingfisher composite decking is not only a beautiful addition to the home, but can offer many advantages over traditional wood decking.

It is crucial to know how to properly care for a composite deck and taking the right steps will make all the difference.

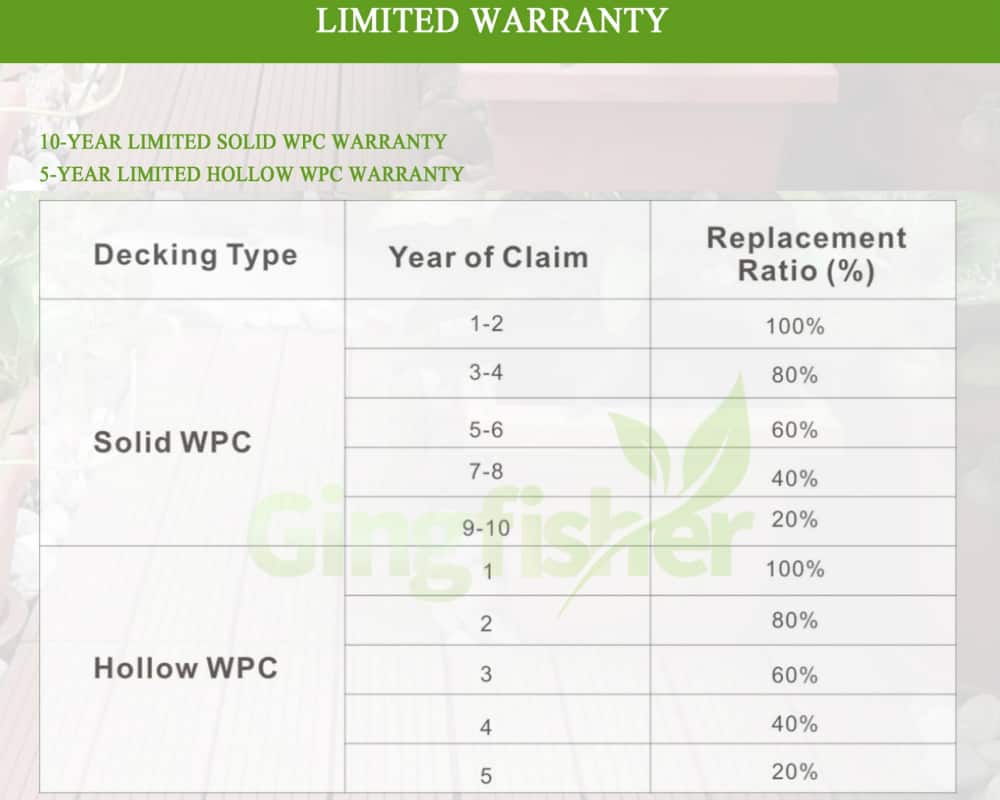

Some retailers or sales agents like to use the term of the warranty as a marketing gimmick, they tell you they offer a 25-year limited warranty but then you need to read the fine print to find out what sort of warranty you are really getting.

Who can tell us what will happen after 25-year? Some companies even don’t have such longer history so how to guarantee quality? We truly doubt it.

If warranty is just a number, why not we offer 30-year, 50-year or 100-year warranties?

As manufacturer in China, we are specialized in composites production and R&D, we are not good at marketing. Gingfisher composite timber decking is protected by a 10 year limited warranty. Knowing that any such problem will normally show itself within the first 1-2 years of the products life means that the Gingfisher warranty period of 10 years has you covered more than five times over.

The warranty is unlimited and based on the simple premise that if a manufacturing fault becomes apparent during the warranty period, Gingfisher will make sure that it is fixed.

Simple, easy and “no fuss”.

When you strip away the marketing jargon and look at the real value of the warranty, Gingfisher stands out on the ground support, genuinely prepared to help, if support is ever needed.

For more details of warranty please contact with Gingfisher sales team directly/ info@gingfisher.com

Trusted Partners

This is the Century of Qualiy.

When you want longevity in a market, the only thing that will get you there is your customers’ satisfaction—-consistently. And the only thing that creates consistent customer satisfaction? Quality.

That’s why Gingfisher became trusted partner of big supermarket, retailer giant and bran distributors.

Get A Quote Today

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.