Direct from Source, Direct to Profit

Superior wpc manufacturer

Kickstart Your Project with Just 100 sqm of WPC decking and Wall Cladding Today!

Chosen by Top-tier Building Supermarket Chains

As an established supplier for leading Building Materials Retails chains, Gingfisher offer superior quality wood plastic composite (WPC) materials trused by leaders. You'll benefit from our wealth of expertise and commitment to quality, ensuring your projects stand out from the competition.

Reliable supply to Keep your Project Moving

With an annual production capacity of 38,000 tons (approximately 1,500 containers) ----Gingfisher have the infrastructure and capabilities to keep up with your demands, no matter how big or small. Our 70 extrusion production lines ensure a reliable, continuous supply of our top-quality WPC products.

Factory-Direct Pricing for Unbeatable Value

Gingfisher is real WPC manufacture based in China, No middlemen. Exceptionally crafted WPC products at the source for unsurpassed value. We offer flexibility in customization for your projects. We're committed to giving you value for money with every purchase, ensuring the best return on your investment.

What We Offer

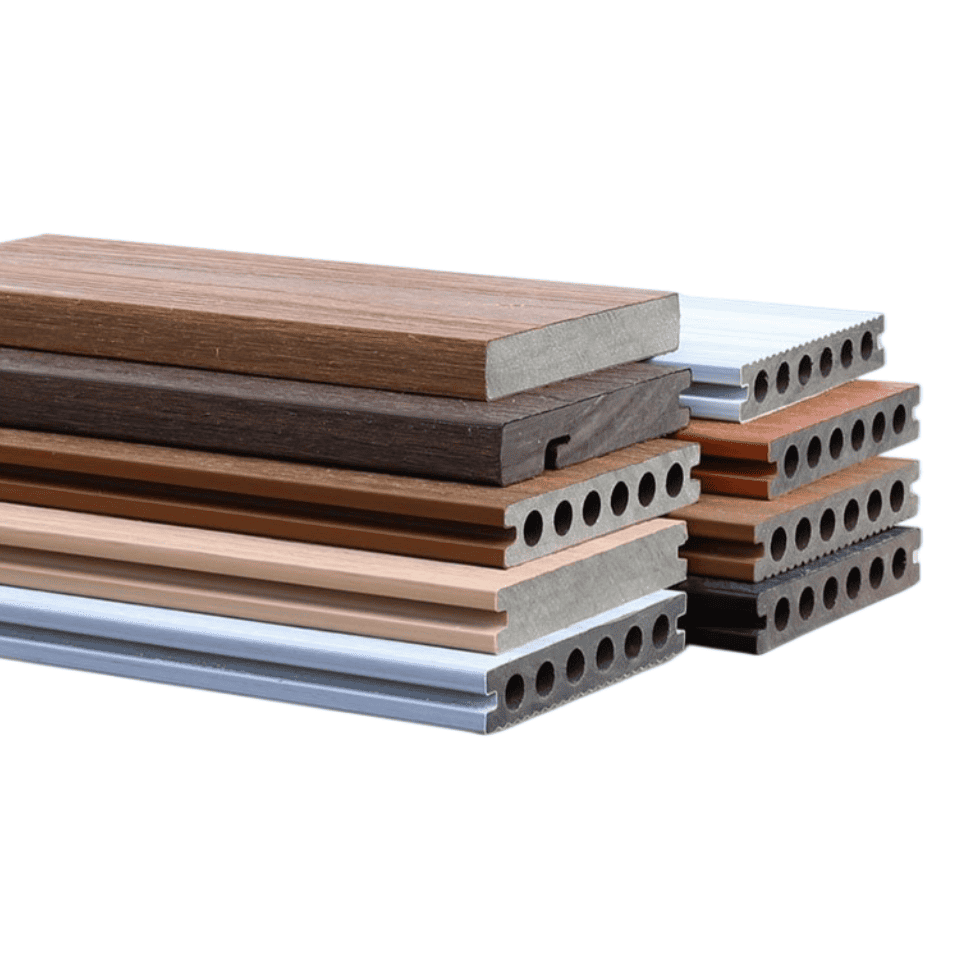

OUR Products

Why Partner with Us?

Discover the Unmatched Benefits

Expertly-Optimized WPC Formula

With a rich history in the industry, we have perfected our unique WPC composition. Our proprietary formula incorporates first-grade recycled plastic pellets, sourced globally, ensuring the pinnacle of material quality. Meticulously engineered, our blend resists UV radiation and aging, securing the longevity and vibrant color of your projects. Our commitment to excellence is embodied in this robust formula, underlining the superior durability and enduring aesthetic appeal of our WPC products.

Excellence Backed by Renowned Certifications

Our WPC products don't just meet, but exceed industry standards, proudly boasting Intertek, SGS, CE certifications. Moreover, our manufacturing facility adheres to the stringent standards of ISO14001 and ISO9001. With BSCI certification, we validate our commitment to ethical practices. Equipped with over 20 different advanced international testing instruments, including US-made QUV Accelerated Weathering and Xenon Light Testers, ensuring reliable product integrity.

Effortless Assembly & Customization

Gingfisher WPC products are meticulously designed for streamlined installation, aiming to significantly save your time and labor costs. Enhance your competitive edge with quicker project turnaround effortless installations. We provide an extensive range of accessories, the ability to customize board lengths, colors, and wood grain patterns to fit your unique requirements. What's more, to make your job even easier, we offer factory pre-installation services including pre-drilling and grooving.

Solid Foundations, Reliable Partnerships

25-Year Warranty

Our Clients Believe in Us

Here Is What They Are Saying

Crafted with Care

Dedication Defined in Our WPC Production

Step 1: Raw Material Inspection & Blending

Step 2: Profile Extrusion

Step 3: Surface Finishes

Step 4: Safety Packaging is Our Priority

Step 5: Superior container loading capacity

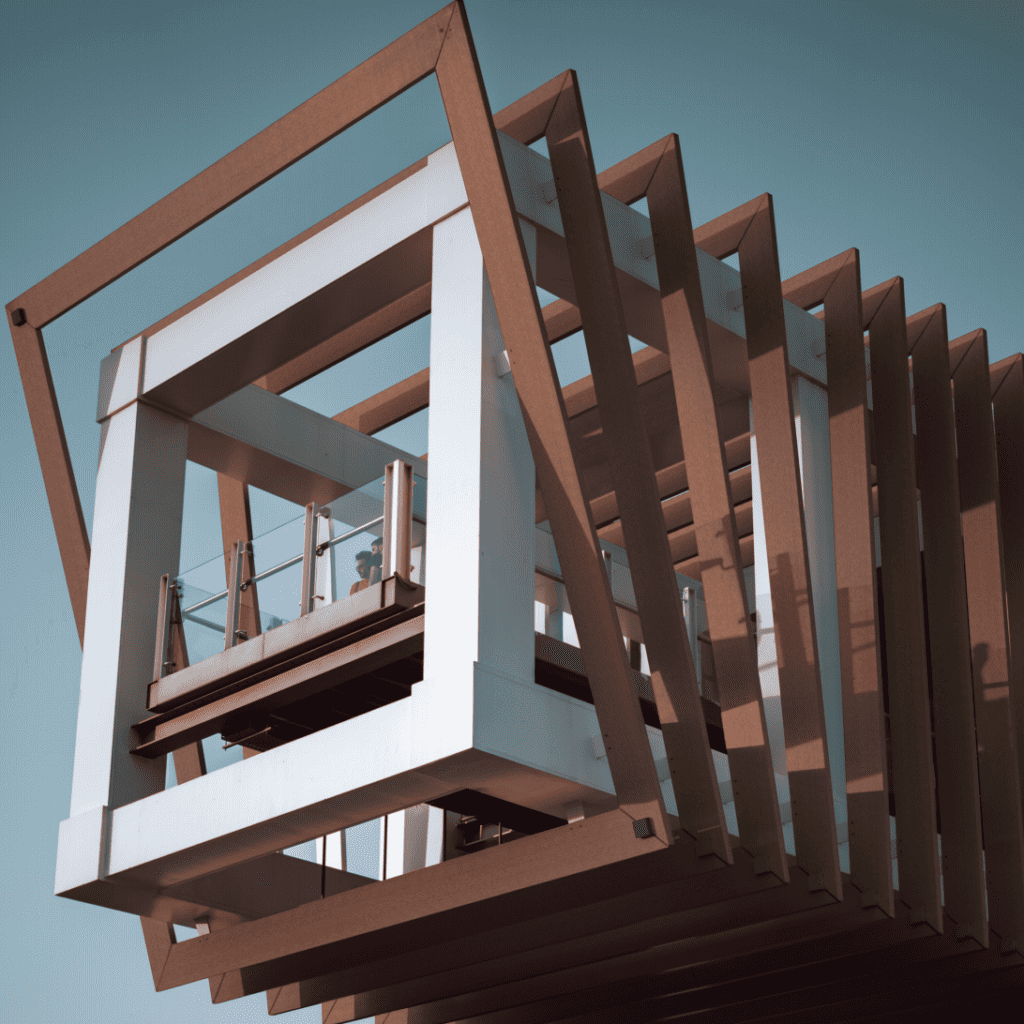

Innovative Applications of WPC

Global Use Cases & Success Stories

Supermarket Application

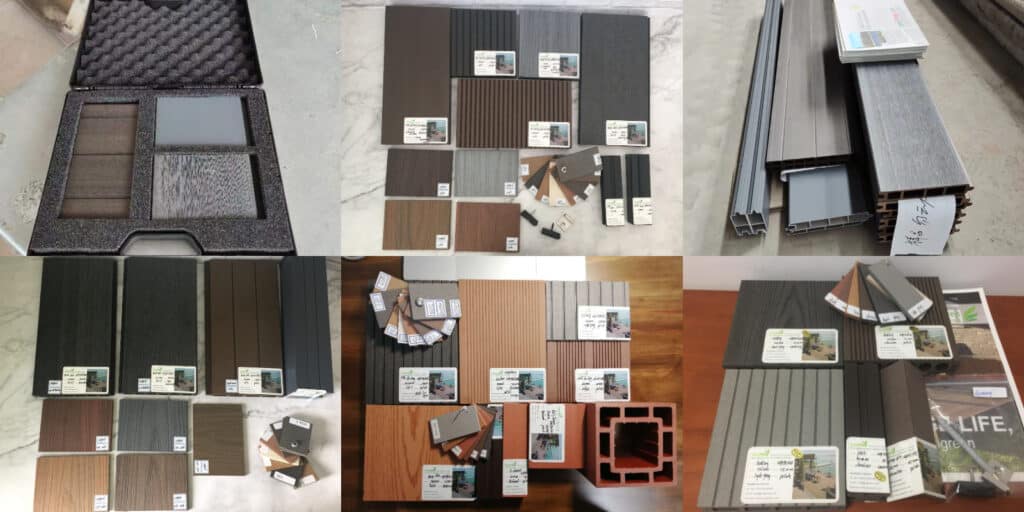

Retail Showroom Display

Construction Site Usage

USA

Aruba

France

Spain

Chile

Australia

We've Assisted Hundreds of Clients with Tailored WPC Solutions

Exceptional. Durable. Sustainable

Diverse Aesthetic Choices in WPC Manufacturing

Embrace a Rich Array of Colors and Authentic Wood Grain Patterns

Request your free sample now!

Start Your Successful Journey with Gingfisher through 3 Simple Steps

Step 1: Share Your Vision

Inform us about your project – the nature, the estimated quantity, your preferred materials, and any special requirements you may have. We’re dedicated to streamlining the process.

Step 2: Obtain a Customized Quote:

We provide an accurate, detailed quote based on your project specifications. We prioritize transparency and precision to ensure your understanding and satisfaction.

Step3: Review Samples & Initiate Production:

We’ll present product samples for your approval, meticulously considering every detail such as color, pattern, and size. Once approved, we manage the full-scale production, vigilantly monitoring every step until the products safely reach you.